Our Cleaning And Test Process

External Cleaning

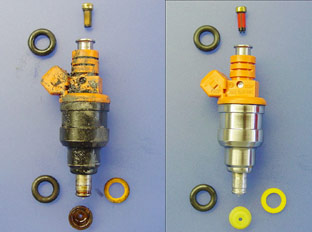

The fuel injectors are externally cleaned in a special detergent and are visually inspected.

Test Electronics and Solenoid

We test the fuel injector’s coil for resistance, shorts, and current draw. A fuel injectors’ coil (solenoid) can pass a resistance test, but still fail when run under load. We check the fuel injectors’ coil winding under a simulated load, and we are able to detect intermittent fuel injector coil faults.

Wire Brush Cleaning

We wire brush any loose paint and rust from metal fuel injector bodies. Plastic fuel injectors skip this step.

Remove Filters and O-Rings

Reclean

The fuel injectors are then re-cleaned to remove any particles or dirt that may Contaminate the cleaning fluid in the next step.

Ultrasonic Cleaning

The fuel injectors are placed into an ultrasonic cleaning tank where they are electronically cycled on and off while being ultrasonically cleaned with special detergents. This allows the ultrasonic waves to agitate and dislodge any particles and buildup outside, and more importantly, inside the injectors.

The running injectors cause backflushing of the cleaning fluid where the dislodged dirt, carbon, gum, and varnish is pushed out of the injector. This ultrasonic cleaning is performed for a minimum of 30 minutes depending on the condition of the injectors.

This cleaning step will be repeated a second time if the fuel injectors fail either the leakdown test or the flow test in the next step.

Flow Testing

- Leak Down test– is performed at 60 to 80 psi. When in closed position, fuel injectors should not leak any fuel.

- Spray Pattern and Atomization of Fuel

- Flow Rate – The volume of gas each injector flows in cc/min at 43.5 psi / 3 bar of fuel pressure. For proper engine performance the injectors in a set should be flowing within 5 percent of each other. OEM injectors are designed to flow a volume within 2 percent of each other.

Record Results

The results of the flow testing are then recorded on an test data evaluation sheet.

- Injectors that fail either leak down or flow testing are separated and labeled as not serviceable / defective.

Re-assemble With New Parts

Install new filter baskets, o-rings, and pintle caps ( if the parts are commercially available ).

Injectors are lubricated to increase shelf life.

Pack and Ship

The fuel injectors are then packed along with the old parts for return.